In September 2013 INSPECTOR SYSTEMS carried out wall thickness measurements on safety-relevant nuclear power station pipelines for IntelligeNDT Systems & Services GmbH, a globally operating company in the field of non-destructive materials testing in the nuclear power station sector.

The wall thicknesses of the pipes, which are not accessible from the outside, were measured with the aid of a combined ultrasonic and eddy current inspection robot.

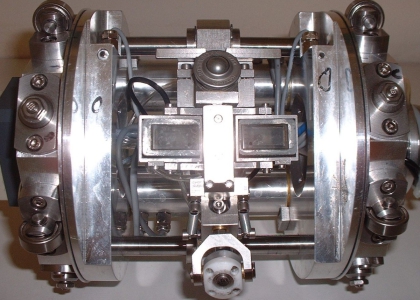

For this purpose INSPECTOR SYSTEMS adapted a test module from IntelligeNDT Systems & Services GmbH to the existing type 3000 drive system. The resulting inspection robot is able to carry out complete wall thickness measurements on pipes in a diameter range of DN200. Thanks to the tried and tested INSPECTOR SYSTEMS drive technology it can travel through 90° pipe bends with a bending radius of 1.5D as well vertical pipe sections.

In the area to be examined, two contaminated pipelines with an internal diameter of approx. 190 mm were inspected over a length of around 30 metres in each case. In order to achieve complete wall thickness measurement several 90° bends had to be traversed. This posed no problem at all for the INSPECTOR SYSTEMS drive technology.

Most of the equipment could be decontaminated after deployment so that the inspection robots are available for further use. Only a few parts which came into contact with the inner wall of the pipeline, such as the drive wheels of the inspection robot, could not be decontaminated.

This project has once again demonstrated the great advantages of the flexible and modular design of the INSPECTOR SYSTEMS inspection robots. Because of this design and the many years of experience of internal pipeline inspection, it was possible to put together an inspection robot from existing modules within the space of just three weeks. Technically this met the strict requirements for use in the nuclear sector.