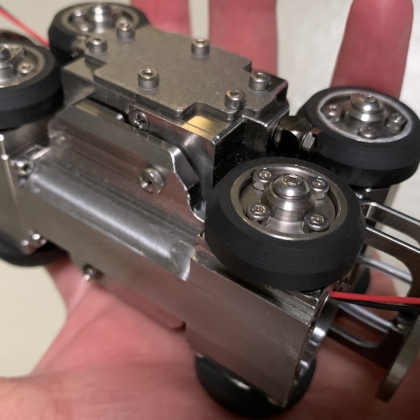

Versatile know-how – state-of-the-art technology: What started as a one-man company in 1983, has developed to a well-established medium-sized family business today. The company has made a name for itself on the global market as a provider of customized solutions and innovative pipe robots for the inspection, non-destructive testing and reworking inside complex pipe systems.

Whether sales or service – as a long-term partner of various major and internationally operating corporations, and thanks to the expertise of our engineers, technicians and specialists, we are in a position to offer customized developments and complete solutions from a single source. For this, we operate an in-house design and development department and also our own mechanical manufacture and electrical workshop. Diverse certificates and approvals, e.g. in the nuclear power and offshore industry, are proof of the high-standard and reliable services provided by INSPECTOR SYSTEMS.

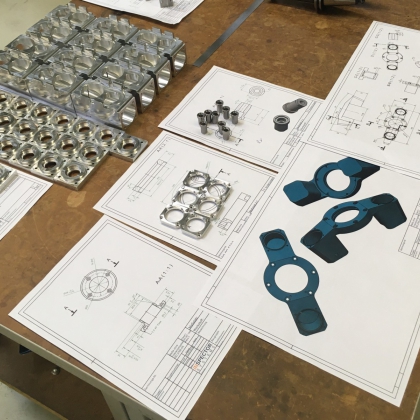

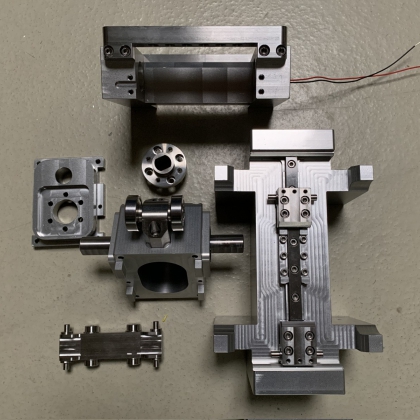

Heart of the company – the manufacture

Beautiful and shiny alone do not suffice as quality criteria, though. In its basic structure, a pipe robot from INSPECTOR SYSTEMS is a sophisticated machine of an excellent quality standard, which has been refined and perfected over the decades. On the one hand, the secret lies in our experience and know-how in the development and design of pipe robots spanning over many years, while on the other hand, we pride ourselves of our advanced manufacturing technology including precise planning and preparation of all manufacturing processes where even the smallest details are considered. From the beginning, our philosophy has been to ensure the highest possible vertical range of manufacture at our company location.

A pipe robot is made up of hundreds of mechanical, electrical and pneumatic individual parts, large and small, some with a very specific geometry, which must be joined seamlessly and must perfectly fit each other. With our state-of-the-art machinery, comprising the latest vertical and horizontal CNC machining centres, we are able to execute even the most challenging custom-fit component and can also cater to special customer requests at any time.

Always on the move

Nevertheless, it is not only the use of high-performance manufacturing systems that ensures consistent adherence to our high quality standard. Quality is a basic requirement for ensuring the satisfaction of our customers, which begins with the selection of suitable materials and ends with one of our most important quality features – our highly qualified staff. The highest demands in terms of service focus and quality are paramount in this context. We are therefore committed to a process-oriented management system to continuously improve our quality performance. Efficient organisation, constant improvement of processes and work sequences ensure Top-Quality, the benchmark for action at INSPECTOR SYSTEMS.